Small parts without great effort Do you want to fabricate small parts from aluminium profile rod? Will the small parts require processing – maybe even on their face side? With the eluCad programming software, the special program “Software Cycles” and elumatec rod processing centres, all that is fast and accurate. Small part manufacture is an automatic process that need not be monitored by the machine operator. Particularly suitable for this process is the SBZ 151 5-axis rod processing centre from elumatec, whose tools include a saw blade .

The machine manufacturer elumatec AG offers the SBZ 151 with a machine bed up to 16.30 in length – at that size, both very large and very small parts can be processed on the same machine. In addition to the 6-sided processing of very long profiles, this versatile machine is suitable for use in combination with the eluCad programming software to fabricate small parts quickly in large lots. In this so-called cycling, the small parts are first machined on the profile machining centre, then sawn off the rod. The SBZ 151 saws right through a special clamp that is provided for this purpose and appropriately designed. The cut small parts are caught on a special tray so that they cannot fall into the machine bed. The program for software cycling comes from the programming software eluCad. Four different modes can be selected, ensuring speed and accuracy. The process is automated and needs no monitoring. This allows small parts to be fabricated quickly and with precision.

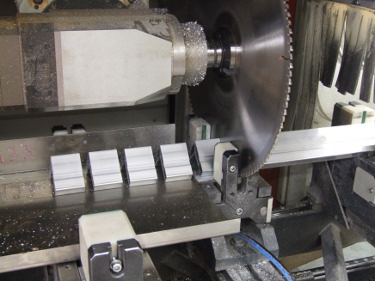

Quick fabrication of small parts on the elumatec SBZ 151 rod processing centre: Accurate sawing with the automatic fixture – then a sheet catches the small parts so they won’t fall into the machine bed. |

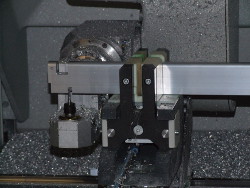

The first two fixtures hold the so-called cycling tray, while at least two fixtures hold the profile rod. |

4 modes of software cycling

After program start, small part fabrication on the SBZ 151 runs automatically: The saw blade saws through the cycle fixtures and the separated small part is caught by the cycling tray. Then fixture 3 moves to the right by the desired part length. Fixtures 1 and 2 follow, carrying the capture sheet and moving close to the rod. Another saw cut, and the cycling tray catches the small part again. This process repeats until fixture 3 can no longer move to the right because fixture 4 is in the way. The SBZ then moves the fixture out of the way, always being sure that the profile rod is held by two fixtures. The program slides superfluous fixtures to the right of the rod. If the remaining piece becomes too small before the required unit count is reached, the software cycle program stops.

Of course, at some point the holding capacity of the cycle tray for small parts will be reached. Then the machine operator can simply take the sawn-off small parts on the tray and push them forwards or take them down. This quickly makes room for new parts.

The eluCad software provides four different procedures for small part fabrication. In addition to Mode 3 just described, Mode 4 also uses a cycling tray so that the cut small parts don’t fall into the machine bed.

Mode 4 also permits processing steps from the left: First, the spindle performs all the programmed processing on the small part. If machining is needed on the face, the first two fixtures associated with the cycling tray move to the left so that the spindle has enough space to work: The spindle swings into the resulting gap and works on the face. After the small part has received all the processing it needs, both fixtures move with the capture sheet back to the rod and the final separation cut takes place. Since the profile rod is not moved, Mode 4, like Mode 3, is characterised by high precision.

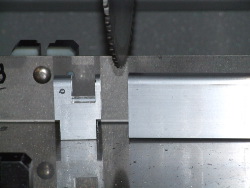

“Software cycling” means the fabrication of small parts: The small part first receives all the necessary machining – even from beneath, with the angle head. In the next work step, the small part is sawn off the rod. |

In cycling, the elumatec rod processing centre SBZ 151 saws through a special clamp specifically designed for the purpose. |

A finished small part, after it is sawn from the rod. The cycling is controlled by the eluCad programming software. There are four different working modes from which the user may choose. |

In Mode 1 and Mode 2, the system uses no cycling tray: In Mode 1, eluCad distributes all the fixtures used over the rod. Then the saw cut moves through the cycle fixture, and the cycle fixture moves to the right by the desired single part length. Another saw cut, the cycle fixture moves again – this process repeats until the required unit count is reached. In Mode 2, the cycle fixture does not move along the profile rod: Instead, the fixtures push the profile rod to the left by the desired single part length, through the cycle fixture.