– Production oversight with the customer

The introduction of eluCad in a company generally follows a well-understood procedure. First the machine operators who will work with the eluCad programming software on an elumatec rod processing centre come to a semainar in Dettenhausen. Once the machine has been set up at the customer’s premises, an elusoft employee travels there to oversee production. The customer’s machine operator thus always has a competent contact person at his side during the difficult familiarisation phase. Important questions can be answered quickly. Company-specific questions can also be cleared up immediately. Do you want to read a detailed report on the topic “Production oversight”? Easy click here.

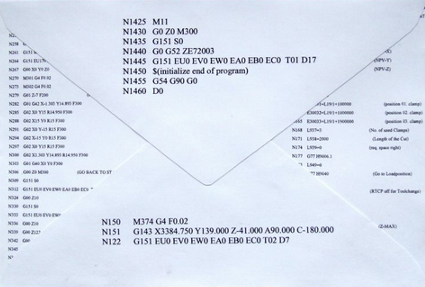

– ISO-code training

The ISO code is a sequence of command lines consisting of alphanumeric combinations for the control of CNC machines. The ISO code seminar offers “help for self-help” for smaller program changes, on the principle “Give a man a fish and he eats for a day, teach a man to fish and he eats for a lifetime.” With the knowledge gained from ISO code training, you can make small program changes yourself or write your own small programs. In general, eluCad users need no programming skills – the entry of data in appropriate windows suffices. The ISO code seminar is something for interested people who “want to know a little more” and want to get into the material to a greater depth.

your own small programs and modify machine code.

You’ll be able to work more effectively than ever.

– Development of interfaces to software products that are used in the industry

In the company-internal data flow, unsereThe eluCad programming software is the bridge between the rod processing machine, which after all executes processing programs, and the programs for design and work preparation that are used to develop and concretise product ideas. The software world is large and complex, and subject to frequent, fast change: Our industry has programs such as LogiKal, Schücam, Wictop, Hueck-Tec, Stijene, C-Mol, Jopps, MAP, Picos FTF, CAD-Plan Athena, ISD Hicad Hicam, Graitec DSC, Bocad and products from still other suppliers. Only when the output formats of such programs can be directly processed by eluCad can the company-internal data flow work quickly and without loss. For these processes to succeed as well as possible, as interface experts we can write conversion programs for software used upstream of eluCad.

– Starting of programs and ensuring that the milling results are good.

– Development of production-specific software

Do you need a special program, for example to cool a tool for flowdrilling? Do you need a saw cut from two sides because your profile is so wide? Do you need help with the processing program for shuttle operation? – Ask us – we can provide solutions for your fabrication problems.

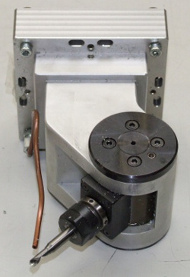

Angle head for the SBZ 122: That allows even slanted surfaces to be processed

– Integration of special equipment on the machine

Sie need a steel saw blade with extra support surfaces, special angle heads or a vacuum table for processing of small parts? We ensure that optional equipment can be used effectively.

– Development of special solutions

Example: Island clamping. Do you want to place the fixture close to the processing point so that the profile can pivot as little as possible and profile processing can be extremely quiet, for example in a small workshop? We develop special solutions for your needs.

– Support for problematic orders

Is your customer complaining because he doesn’t like the milling surface appearance or tolerances were exceeded? Ask the experts at elusoft – machine technology or software technology tricks can help with difficult orders.

– Software adaptation for customers

– Development of products that simplify profile processing with elumatec machines