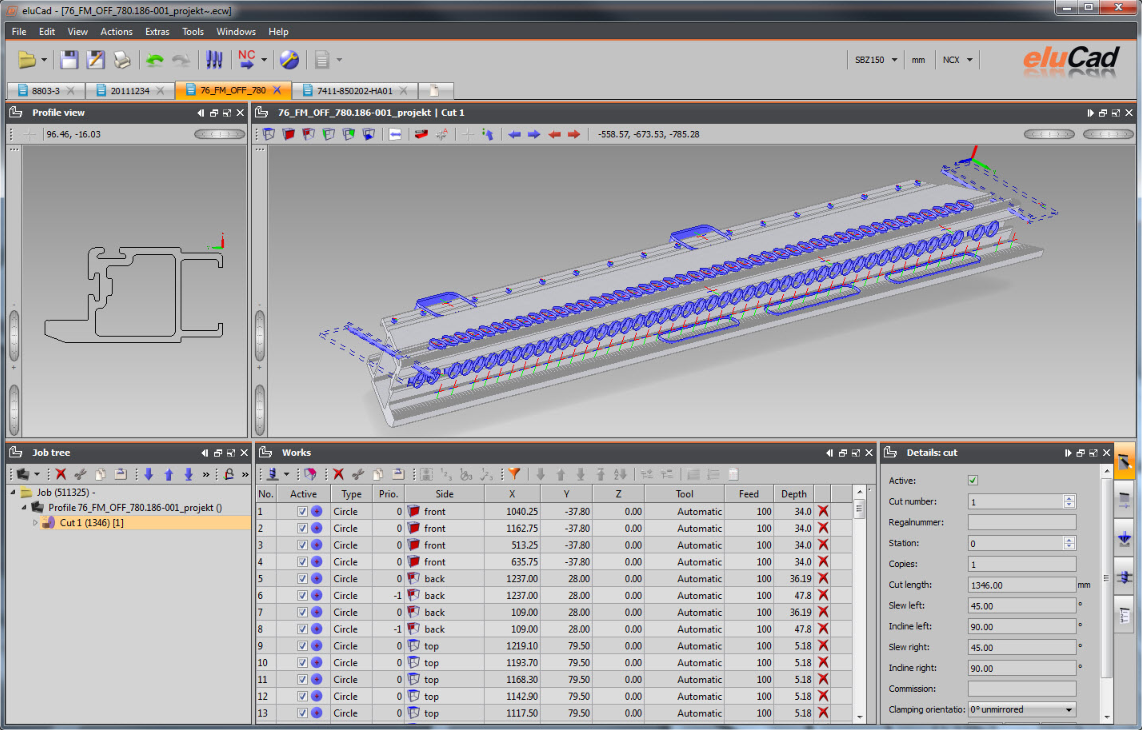

eluCad programming software

eluCad is an application which simplifies the programming of profile machining centres. This user-friendly software is designed to allow the user to avoid writing their own ISO code – the user must simply enter data into the program’s user interface.

eluCad is characterized, among other things, by the largest possible flexibility, operator-friendliness and practice-oriented functionality. Profile processing means the removal of material from the profile bar where the customer would not like material to be. eluCad simplifies this process. Profile views can be uploaded from a profile database, new profiles can be simply loaded into the programme. Machining processes such as holes, circular pockets, slotted holes or grooves can be called up by pushing a button. For these standard processes, the programme queries data such as length, width, diameter or immersion depth in transparent input fields. The machining can be quickly and precisely placed with data for axis positioning.

Freely programmable contours, so called free millings, can also be laid out just as clearly. The software queries all the required parameters for their generation. eluCad independently calculates the tracks for clearing standard processes or determines that firstly drilling is carried out and then threads are cut. Similarly, you can easily program pocket millings, which removes the material within the surface of a given shape, including a two-step process that first removes the brunt of the material, the so-called Roughing step, and a subsequent Finishing step that leaves you with a smooth surface and edge contour.

Intuitive to use, clear presentation, customisable. With eluCad, processing programs can be created quickly and easily.

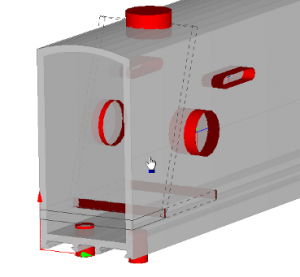

3D view

3D view is integrated into eluCad, displaying the designed parts realistically on the screen: These 3-dimensional displayed parts can be turned, reduced in size or zoomed in on – just like the observer wants. In the 3D model the position of the X, Y and Z axes are also shown; this supports the ability to visualise and makes the data entry easier.

The transfer of data out of a design drawing by hand into the eluCad program is one possibility for data entry. eluCad can also use different interfaces to retrieve data from different design and calculation programs used by customers, and process the data further.

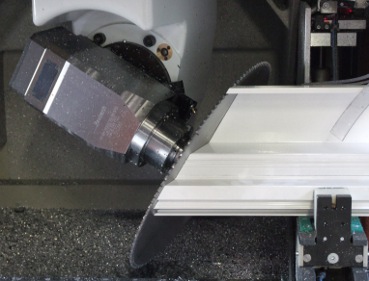

Tool optimisation: eluCad selects the tool with which processing can be carried out quickly and precisely.

Optimising software: Tool and path optimisation

eluCad generates the program based on the detailed industry knowledge of the software developers. eluCad optimises programming of the target machine in many aspects: The software programme determines a tool selection for processing that prevents tool exchanges when possible. A 14 mm hole and a 12 mm hole are, for example, both produced with a 10 mm tool, if this is clamped straight and is also good for machining. Only the results of work counts, and on the way there much time can be saved with fewer tooling changes.

Even path optimisation belongs to the strengths of eluCad: The programme calculates the fastest pathways between processing points. In all processing steps, the programme avoids unnecessary re-clamping of a profile bar, a pre-requisite for time-efficient and precise fabrication.

Collision control

Included in eluCad functions is collision control – for this the software calculates if machine parts or clamping elements are in the movement path of the machine. This prevents expensive machine crashes and downtimes. If a part to be manufactured is correctly programmed, thanks to eluCad it can be manufactured quickly with the same quality on a selected machine in the company’s machine shop. A business can quickly process high volume production jobs.

Set up new tools simply

New tools can be set up simply in eluCad. Because the programme requires comprehensive information such as cut length, immersion depth, diameter, total length and data for tooling acceptance for example, new tools must be calibrated into the system. Multiple-side machining, machining on pipes or angle parts – eluCad offers functional solutions for effective machining processes. Repeating processes are grouped into macros and stored in a database.

The finished profile. eluCad creates the processing program for the machine.

The processing steps were entered into eluCad with simple data entry.

Sind all the parts for a job are programmed, the machine code must be generated from this dataset.

In eluCad, that’s easy: Select the target machine from the suggestion list – and then just press the NC button. A window with the generated control program for the target machine opens immediately. If a company’s machine inventory includes multiple rod processing centres, eluCad can also be used to determine a specific target machine for the production order.

eluCad module

In addition to the standard version, eluCad also offers different modules for different applications. These modules can optionally be purchased when a customer needs one. It is also possible to lease our products; the rental price is included in the software maintenance agreement. The following eluCad modules are available:

- Clamp management

- Rod processing

- Bar optimisation

- 3D-Import

- DGX module: This module generates DGX files used to control sawing.

- NCW module: This module makes it possible to import NCW files from upstream software into eluCad. The files are then further processed in eluCad.

- ECW module: This module makes it possible to import ECW files from upstream software into eluCad. The files are then further processed in eluCad.

- CSV module: This module makes it possible to import CSV files from upstream software, such as Excel lists, into eluCad. The files are then further processed in eluCad.

- WIC module: This module makes it possible to import Wictop files into eluCad and process them further. Wictop is a file format for the window construction software provided by Wicona.

- SCH module: This module makes it possible to import Schücal files into eluCad and process them further. Schücal is a file format for the window construction software provided by Schüco.

There are many industries in which aluminium, plastic or steel profiles are processed – eluCad can be used in any of them. The optimising programming software is marketed worldwide, and so eluCad is available in different language versions.

Our programming software eluCad and elumatec continuous machining centres are a highly refined combination

at a modern stage of development.

elusoft GmbH always strives to provide their customers with a powerful, easy-to-use programming software that meets market requirements. eluCad is therefore continually further developed with great care and offers an efficient, modern tool for daily work. New program versions are reactions to market requirements or customer requests. They help users make even more cost-effective and efficient use of their rod processing centres, to work faster, more accurately, more safely and more easily.

eluCad users have the option of purchasing a software maintenance agreement that entitles them during the duration of the contract to upgrade to a new program version as soon as it is available. eluCad can be configured to notify users automatically when updates are available.

A software maintenance agreement provides eluCad users with the following advantages:

- Regular updates in small steps

- The current version is always in use

- Preferred support when calling the elusoft support hotline

- elusoft support staff can help not only by telephone, but can also use Teamviewer® over the Internet to switch to the customer’s programming workstation (if the customer permits it)

- faster support is possible, because the supporters know the most current version the best

- annually a free place for 2 days in a group training for advanced training for more employees

- During peak order times, eluCad users can use an additional seat license for four weeks free of charge. This offer is valid once per year.

The software maintenance agreement has a duration of one year at a time and is automatically extended if not terminated three months before expiration.

System requirements

eluCad 3.1 or higher:

- Microsoft® Windows® 8 / 8.1 / 10

- Microsoft Windows 8 / 8.1 / 10 Pro

- Microsoft Windows 8 / 8.1 / 10 Enterprise

CPU Type: Intel® Core i5 @ 3.2GHz // AMD FX-8350 @ 4GHz or higher

Memory: 4 GB (8 GB recommended)

Display Resolution: 1024×768 (1600×1050 or higher recommended) – NOTE: Windows UI Scaling, often used for resolutions larger than 1920×1080, may lead to UI scaling issues.

Video Card: Minimum: OpenGL 3.1 supported video card // Recommended: Nvidia Geforce GTX 760 / AMD Radeon R7 260X v3 or higher

Disk Space: Installation 1 GB

Network: Internet via DSL

eluCad 2.1 or higher

Operating System

- Microsoft Windows 7 Enterprise

- Microsoft Windows 7 Ultimate

- Microsoft Windows 7 Professional

- Microsoft Windows 7 Home Premium